Products –

Bandsaw-Technology

Highest precision & versatility

CANALI – A worldwide term for high-performance band saws

The machine factory Gebr. Canali, Maschinenfabrik was founded in 1945 at Speyer, Germany. Through superior engineering and quality workmanship Canali became soon a leading bandsaw manufacturer worldwide. Well over 10,000 bandsaws were manufactured and commissioned over the years. From Patagonia to Malaysia, Canali machinery is operated in nearly every country in the world. Möhringer continue this great tradition, manufacturing and trading the Canali brand since 1999 with great success. The classic range of products has been broadened by implementing innovations for new applications and developments, i.e. thincutting bandsaws, loading systems, etc. Möhringer offer the complete range of sawing technology such as chipper/canter, circular, bandsaw and framesaw technology.

With the acquisition of Braun-Canali band saw technology, we have completed our program and are now able to offer you, as a complete service provider, the full diversity of modern cutting technique.

We will lead the first-class technology, known as Braun-Canali, to new applications.

Log band saw technology

Highest quality for THE PROCESSING of big diameters

For sawmill, planing mill and secondary processing

Flexidrive

Universal log carriage for all applications

The log carriage FLEXIDRIVE is the specialist for soft- and hardwood: high flexibility, gentle log manipulation, precise cutting!

Log band saw technology Accessories

Future-proof and modularly expandable

Circular saws, Chipper canter head, Scoring circular saw & Automatic control

Resaws

Vertical or horizontal

Single, twin or quadro – For sawmill, planing mill and secondary processing

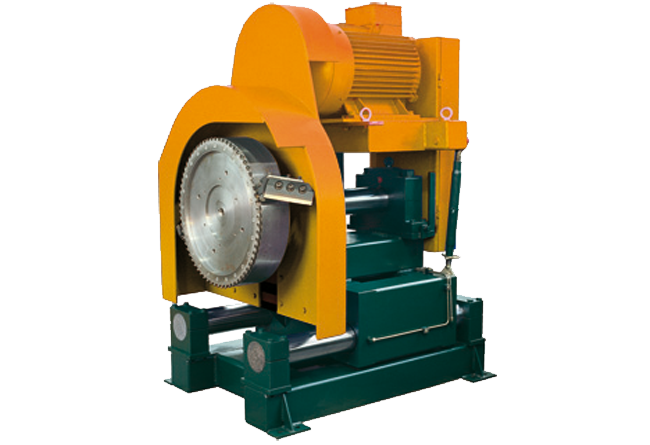

Reducer Bandsaw

For sawmill, planing mill and secondary processing

For each band saw there is a digital hydraulic positioning unit that allows a precise and fast adjustment.

Thincutting Band saw

Small saw kerf, high precision

Thincutting band saws are designed for highly precise production of high-value products, i.e. parquet lamellas, strips for floorboards, door components, saw-cut veener, pencil timber, parts for music instruments.

Additional processing steps like debarking and butt-end reducing can be easily controlled by the operator without influencing the sorting speed. The prepared logs are sorted according to diameter and quality classes and are then ready to be sawn.

Band saw technology Examples for Applications

LOG BANDSAW TECHNOLOGY – Application in the saw mill

Band saw with log carriage

- Vertical and horizontal

- Cutting of european hard wood

- Cutting of soft wood )

- Cutting of exotic timber

- Seperation of glued timber

Resaw technology

- Planing mill:

Separation of rawly planned timber - Parquet mill:

Separation of strips and production of parquet lamellas - Timber trading:

Separation of preprismatic timber - Saw mill:

Separation of preprismatic timber. Cutting of logs in combination with a log band saw - Glued timber production:

Separation of glued timber, solid construction timber (KVH) etc.

Reducing band saw technology

Band saws (TWIN or QUAD execution) in combination with profiling chippers

Utilisation in hard or soft wood saw mills with a higher cutting performance.